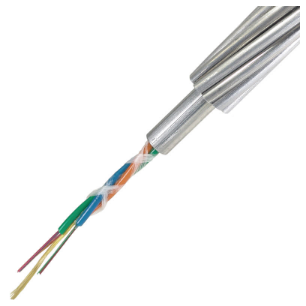

Application of OPGW Wire

Optical fiber composite ground wire [OPGW] is suitable for installation on new power lines with double function of ground wire and communication. Especially for installation on normal voitage and extra high voltage power lines. OPGW can replace conventional ground wire of old power line with increasing fiber communication function. They conduct short circuit current and provide lightning resistance.

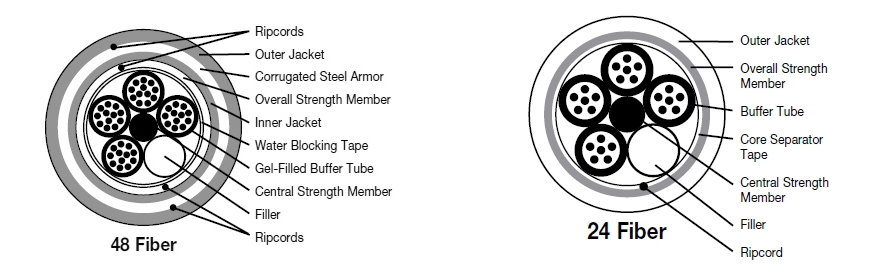

24 and 48 Core Fiber Optic Cable

▪ 12core,24core,36core,48core, 72core,96core

▪ Loose tube gel-filled

▪ -coding per TIA/EIA 598B

Central Strength Member: Epoxy/glass rod

Inner Jacket: Black UV-and moisture-resistant polyethylene (PE)

Armor: 0.006″ corrugated coated steel tape

Outer Jacket: Black UV- and moisture-resistant polyethylene (PE)

Aluma Core Optical Ground Wire (OPGW)

1.Preferred option for easy handling and splicing

2.Thick-walled aluminum pipe provides excellent crush resistance

3.Hermetically sealed pipe protects optical fibers

4.Outer wire strands selected to optimize mechanical and electrical properties

5.Optical sub-unit provides exceptional mechanical and thermal protection for fibers

6.Dielectric color-coded optical sub-units available in fiber counts of 6, 8, 12, 18 and 24

7.Multiple sub-units combine to achieve fiber counts up to 144.

CentraCore Optical Ground Wire (OPGW)

1.Fiber counts up to 96 in same diameter product

2.Small diameter, low weight reduces retrofit impact

3.Laser-welded, hermetically sealed stainless steel tubes provide mechanical and thermal protection for fibers

4.Thick-walled aluminum pipe provides crush resistance and boosts fault current rating

5.Outer wire strands selected to optimize mechanical and electrical properties

6.Fiber grouped in bundles of 12 for ease of splicing prep.

Hexa Core Optical Ground Wire (OPGW)

1.Fiber counts up to 432 or higher if needed

2.Laser-welded, hermetically sealed stainless steel tubes provide mechanical and thermal protection for optical fibers

3.High load, long span capability

4.Each stainless steel tube is uniquely identified for organization at splice locations

5.Stranded wires selected to optimize mechanical and electrical properties of cable

6.Anti-rotational devices usually not required for installation, depending on conditions

Stainless Steel Fiber Optic Tubes

1.Umbilical Cables

2. Downhole Cables for Oil & Gas

3. Towed Arrays

4. High Temperature Cables

5. Hybrid Cables

6. Sensor Cable

7. OPGW

ADSS Cable-All Dielectric Self-supporting Aerial Cable

1. ADSS fiber cables are erect on the same pole with power line in new and old power line.

2. Areas of strong electric field, multi-thunder, etc

Characteristics:

☆ Small cable Dia, light weight, 1,500m span, low attached load on tower.

☆ Tension strength is over 90KN.

☆ Non-metal structure, good insulation, anti-thunder

| Cable model | OPGW-60 | OPGW-70 | OPGW-90 | OPGW-110 | OPGW-130 |

|---|---|---|---|---|---|

| Number /diameter(mm) of stainless steel tube | 1/3.5 | 2/2.4 | 2/2.6 | 2/2.8 | 1/3.0 |

| Number /diameter of AL wire(mm) | 0/3.5 | 12/2.4 | 12/2.6 | 12/2.8 | 12/3.0 |

| Number /diameter of ACS wire(mm) | 6/3.5 | 5/2.4 | 5/2.6 | 5/2.8 | 6/3.0 |

| Diameter of Cable (mm) | 10.5 | 12 | 13 | 14 | 15 |

| RTS(KN) | 75 | 45 | 53 | 64 | 80 |

| Cable weight (kg/km) | 415 | 320 | 374 | 432 | 527 |

| DC resistance(200C W/km) | 1.36 | 0.524 | 0.448 | 0.386 | 0.327 |

| Modulus of elasticity(Gpa) | 162 | 96.1 | 95.9 | 95.6 | 97.8 |

| coefficient of Linear thermal expansion(1/ x 10-6) | 12.6 | 17.8 | 17.8 | 17.8 | 17.2 |

| Short circuit capacity (kA 2聽 s) | 24 | 57.3 | 78.9 | 105.8 | 150.4 |

| Max. operation temperature (C) | 200 | 200 | 200 | 200 | 200 |

| Max. fiber count | 48 | 32 | 48 | 52 | 30 |